Water Treatment Plant 2022

Click the months below to filter through construction photos.

December

The last Plate Settler was placed today.

Concrete placement at the Ozone Contactors Bldg.

Insulated wall paneling being installed at the Raw Water Pump Station.

Flocculation Sedimentation structure Plate Settler hoisted down with a crane

Pipe Gallery at the Ozone Contactors

Maintenance Bldg.

Last section of pipe to Tie in.

November

Finish Water Pump Station

Chemical Storage

Ozone Contactors Pipe Gallery

Infiltration Gallery rebar inspection.

Motor Control Center (MCC’s) installed at the Ozone Bldg.

Maintenance Bldg.

Finish water Pump station metal Bldg.

Vertical Turbine pump assembly

Maintenance Bldg. Under construction

The first sheet rock installed in the Ozone Building

Metal stud framing in the Operations Bldg.

Canopy at the Chemical Storage structure.

Slab On Grade prep work at the Finish Water Pump Station

October

Inside the Sedimentation Basin

Maintenance Bldg. Under construction

Operations Bldg. metal stud framing.

Lime Silo.

Concrete placement at the Chemical Storage

Metal stud framing in the Operations Bldg

Maintenance Bldg

Insulated wall panels installed at the Ozone building

Maintenance building

Electrical duct banks

Meta stud framing in the Operations building

Rebar and formwork at the Chemical Storage facility

Duct bank installation

Prep work for Fire proofing in the Operations Building

Maintenance Building work in progress

Chemical Storage tanks delivered to the site.

Electrical conduits installed at the Flocculation Sedimentation structure.

Electrical duct banks

Work on the Maintenance Building continues

September

The Chem. Storage Building had it’s slab placed last week. They’re cleaning it up and stripping formwork.

The Electricians have been roughing in conduits, unistrut, and installing duct banks between vaults.

The Ozone Bldg. has metal framing and roof being erected

Drying beds Sand media being placed and spread. This is the final layer of material to be placed at this location.

Chemical Storage Formwork and rebar installation has been completed. Concrete to be placed on 9-21 and it will be 650 yards of concrete.

Underground piping and dirt moving taking place

Rebar and form work for Chemical Vault

August

Work currently taking place at the Administration / Operations building

Work currently taking place at the Administration / Operations building

Work currently taking place at the Administration / Operations building

Work currently taking place at the Administration / Operations building

Administration bldg.

Concrete placement for a Chemical Vault.

Administrative Operations bldg.

July

Back fill on the north side of the water storage tank. The vertical pipes are pump cans.

Administrative/ Operations Bldg. CMU (concrete masonry unit) Block construction continues. Administrative/ Operations Bldg. CMU (concrete masonry unit) Block construction continues.

Formwork, rebar installed for Lime silo slab.

Electrical work at the Chemical Storage Electrical room.

Ozone Contactors Structure

Open cut trench for Process piping between the Backwash Equalization and Flocculation Sedimentation structures.

36” raw water piping being welded on site. This pipe comes from the Flow split and is headed to the Flocculation Sedimentation structure

Administrative/Operations building. Contractor is working on the final lift of block and soon the structural steel roof framing will begin.

Administrative/ Operations on the South side

Block being installed at the Administrative/ Operations bldg.

Pump cans at Water Storage Tank - July 21

Process piping around site installed.

June

Ozone electrical room

Pump cans at the Water Storage Reservoir

Ozone Contactors Building

Rebar installation at the Flocculation Sedimentation deck.

Backfill at the 36” raw water line coming from the Flow split to the Flocculation Sedimentation building

Backfill on the north side of the water storage tank around the Pump cans

Formwork for Lime Silo concrete slab.

Concrete masonry units (CMU) being installed at the Administrative bldg.

Block construction underway at the Administrative/operations building

Construction continues at the Ozone Building . Wall forming, rebar installation.

Backfill around the Pump cans and water storage tank

Process piping being installed.

In place density testing at the water storage tank. As the dirt is backfilled it gets compacted and tested.

Block being installed at the Administrative/Operations building

Interior view of the rebar and framework for the Flocculation sedimentation tank.

Process piping being lined up and welded with the canned motor pumps for the Clearwell shown in the background.

Pump cans at water storage tank

Pump cans at the water storage tank on June 16

May

Ozone Building under construction

Water storage tank

The contractor is roughing in conduits in the Ozone Filters Electrical room

Electrical Vaults being installed at the Raw Water Pump Station.

Completed Outfall structure. This structure was built when the TID canal was empty and had to be completed prior to irrigation season.

Water storage tank and Manifold piping being connected.

Ozone Contactors and Filters Building

Placing concrete at the Administrative Building

Backfilling at the water storage tank

Installing wall forms at the Ozone Contactors Building

Rebar curtains being set via crane at the Ozone Contactors

April

Vapor barrier installation at the Administration Building

Construction activity at the Flocculation Sedimentation building

Ozone filters building wall formwork

Electrical room at Ozone Filters Building

North side of Flocculation Sedimentation building

Back Wash Equalization structure

Electrical room rough in for Ozone Contactors building.

Installing rebar mat for wall on East side of Ozone Contactors building.

March

Work underway at the Flocculation Sedimentation Building

Sand Media being placed at the drying beds.

Rebar install at the Ozone Building

Septic System Tank

Formwork and rebar installation at the Ozone Building

Work underway at the Flocculation Sedimentation Building

3. Ozone Filters Bldg. rebar installation With the Clearwell in the background.

Concrete pump placing concrete at the Flocculation Sedimentation Building

A conveyor belt being used to spread rock/sand at the Drying Beds

Aerial view of the work underway at the Water Treatment Plant

Aerial view of the work underway at the Water Treatment Plant

February

Filter slab, installation prior to concrete being placed

Electrical conduits for the administration building

Sludge drying bed drainage layer installation

Under slab conduit installation at the Maintenance Building

Rebar and form installation at the Flocculation Sedimentation Facility

Work under way at the Filter Building

installing drain rock and bed piping at the sludge drying beds

Rebar installation and electrical work underway at the water treatment plant.

Waterproof coating being applied to the Water Storage Tank

Drying bed liners

January

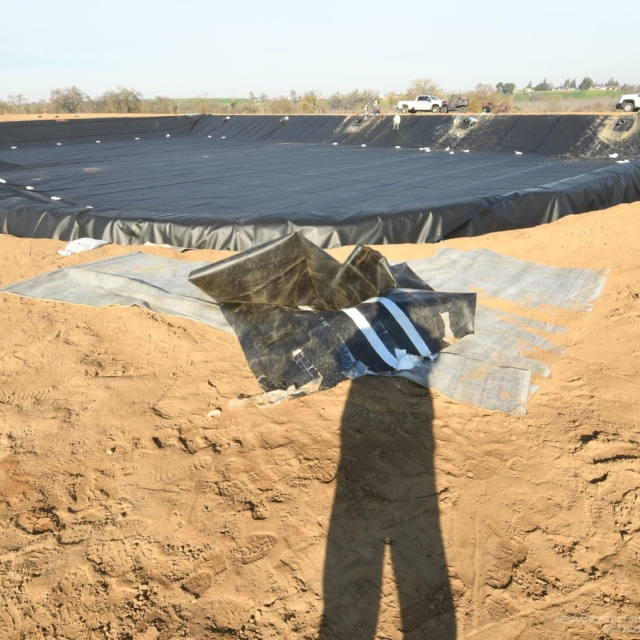

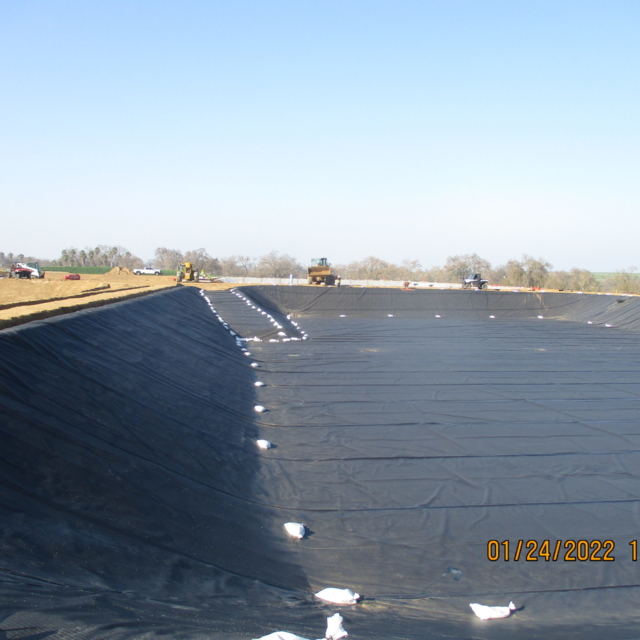

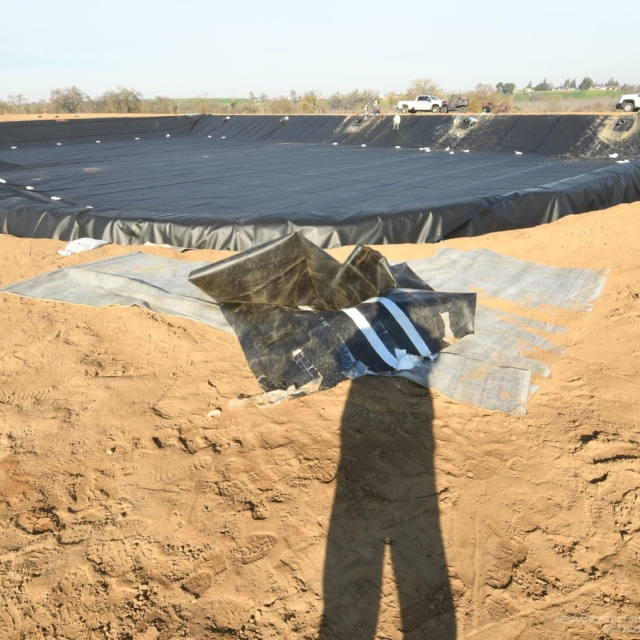

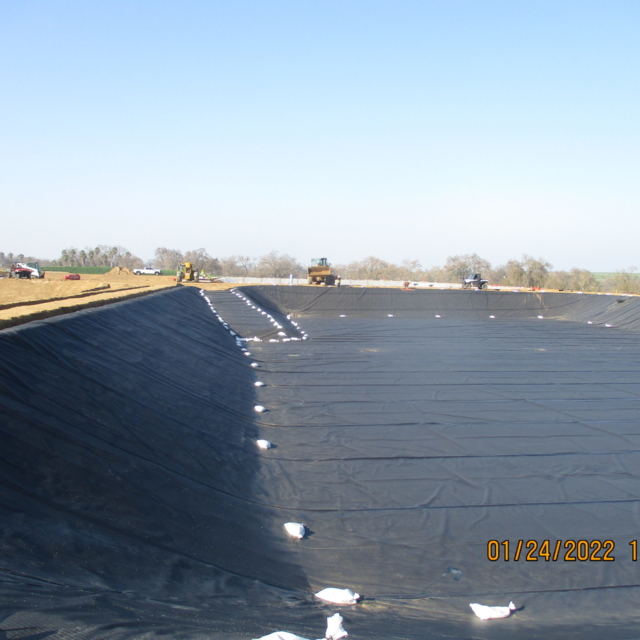

Drying beds liner.

Drying beds liner.

Moving forms at the Flocculation Sedimentation Building

Under slab plumbing at the Chemical Storage Building

Drying beds liner.

Ozone building rebar for concrete slab.

Ozone building rebar installation

Rebar installation at the Ozone Building

Wall placement #2 at the Flocculation Sedimentation facility

Back wash equalization tank constructed and full of water

Ozone Contactors and Filters Installation underway. Underground piping is in, subgrade and the rock section are compacted.

Water storage tank

Ozone building. sub-grade and rock section installation

Chemical Storage and Feed Building. Sub grade is in and base course (rock section) is being compacted.

Maintenance building

Under slab electrical and plumbing drains being installed in the Administrative building

Flocculation Sedimentation Structure

Picture from the Deck at the Back Wash Equalization Building

Outfall Structure (in the TID canal)

Rebar placement for the bottom mat at the Ozone Building

42” FTWM through canal at old Aldrich bridge location. Bridge in the photo is the new Aldrich bridge

Aerial view of the work underway at the Water Treatment Plant- January 2022

Aerial view of the work underway at the Water Treatment Plant- January 2022

Aerial view of the work underway at the Water Treatment Plant- January 2022

Aerial view of the work underway at the Water Treatment Plant- January 2022

Outfall structure